Strengths of Akiba Die Casting

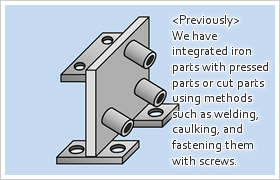

Cost reduction using VE/VA proposals

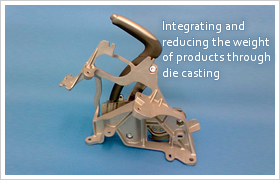

High level die design technology enables us to form maze-like, complex configurations such as those found in valve bodies. We have experience working with domestic as well as overseas manufacturers, supporting proposals for the integration of complex parts, processing parts without performing cutting and reducing the product weight and increasing functionality.

Pushing the limits of heat sink fins

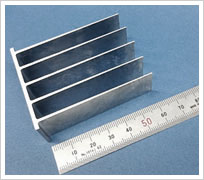

We are steadily raising the standard of thin die cast shapes used for their light weight and heat dissipation. We have successfully tested LED heat sink fins over 50mm tall, with an edge thickness of 0.5mm and a taper of 0.5 degrees using aluminum alloys with a high heat transfer coefficient such as ADC-12.

This picture is of a test sample with a fin height of 60mm, an edge thickness of 0.5mm, and a 0.5 degree taper.

We are confidently accepting orders for various types of heat sinks for lighting and for the automobile industry.

Vacuum casting method

Vietnam and Thailand

2018.01.12

2018.01.12 Happy New Year!

Happy New Year!

2017.12.27

2017.12.27- Over before you know it

2017.12.07

2017.12.07- My car’s fuel and my fuel

2017.11.13

2017.11.13- Foreigners

2017.11.02

2017.11.02- Historical Drama and Gunma

2017.10.27

2017.10.27- Appetite driven Autumn has arrived

2017.10.19

2017.10.19- Struggling with my Aprilia