From Wednesday, Oct. 4th - Friday, Oct. 6th 2017

We will be manning a booth at the Mechanical Components & Materials Technology Expo

Location: Intex Osaka

Hall No.6, Zone B, 38-34 (As part of the Gunma-prefecture booth)

Bringing in 2017, the year of the rooster, I would like to extend my New Year greetings to everyone.

Thanks to all of you our company was able to clear what might be called one life, or 60 years. This year thus marks the beginning of our next 60 years.

In Japan we have converged our technological advancements in mold design, die casting, and plating to master the production of super thin heat sink fins with an edge thickness of 0.5mm, a taper of 0.5 degrees, a depth of 45mm, and 95% emissivity. We have also mastered highly efficient precision die casting of tiny zinc products.

We have organized the integrated production systems at our 3 Vietnamese sites of mold production, die cast, and surface treatment (plating and coating), as well as extending the capabilities of our Thailand facilities to include pressure resistant products (transmission pumps, car compressor housings, etc) and thin walled heat sinks (LED head lamps, etc).

This year we are working to further improve our technological capabilities in regards not only to thin walled, lightweight, and pressure resistant products, but to challenge ourselves to achieve a higher quality, with even the most difficult of industry items. We have eagerly readied our facilities for the high quality mass production of products we are especially experienced with including CVT valve bodies, valve sleeves, and heat counter-measuring heat sinks both in Japan and overseas. We are also furthering our development of heat sinks with extremely thin fins, like the wings of a bird, designed for greater heat emission.

In Vietnam we are improving not only our aluminum and zinc die casting technologies, but also high quality plating (Zn, Ni, PTFE, rigid chrome, Cu/Ni/Cr, etc) and coating (cation electrodeposition, anion electrodeposition, solvent baked paint, etc) for interior and design products. Combined with our well organized system of assembly, experienced in exporting products from pressed, rubber, lost wax, and other metal components, we are ready to take on all forms of customer requests.

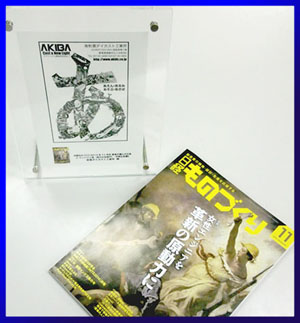

We, the Akiba Die Casting Group, send a prayer for the good health of all, hoping to prosper alongside our esteemed customers, and to garner their continued patronage.

Thank you to everyone who came to see us at our booth during the Business Arena 2016.

We will be operataing a booth at the Business Arena 2016 taking place on Wednesday January the 27th and Thursday the 28th at the Saitama Super Arena. Our booth number will be I-62, near the middle of the arena. We will gladly receive your manufacturing questions and inquiries.

Thanks to all the people and companies that came to visit our booth!

Thanks to all the people and companies that came to visit our booth!

Within the Automotive World 2016

We will be exhibiting at the Automobile Components Processing Technology EXPO

From Wednesday January 13th, 2016 through Friday January 15th.

in the Gunma Next Generation Manufacturing Project Booth

booth number W20-54

Happy new year everyone.

To put last year in one word, “safety.”

As a company specializing in manufacturing we put sincere effort into bringing safety and peace of mind to our customers. We humbly request your continued business.

We use “die-casting” in our slogans, and shall continue to propose functional and well-designed manufacturing methods in regards to die-casting. We are eagerly awaiting your needs for aluminum and it’s superiority for construction, precision, wear resistance, thermal conduction such as with heat sinks, and design products, with high-quality designs.

We are prepared for global strength thanks to our 4 bases in Vietnam and Thailand amidst the continuing globalization evident in the dealings of the TPP. We readily offer services in regards to molds, die-casting, machining, plating, painting, and assembly. All in all, we look forward to your continued business.

I present my new year’s greeting with hopes that we all may share a year of thanks, excitement, and inspiration.

From Wednesday, November the 11th through Thursday the 12th we will be manning a booth at the Manufacturing Partners Forum at the Shinagawa Inter City Hall. Unfortunately it's in the middle of the week, but please stop by if you are near. We will gladly provide support for any manufacturing questions or requests in both English and Japanese.

Our thanks to the many companies who came to our booth last week at Osaka Intex between the 7th and the 9th.

Our thanks to the many companies who came to our booth last week at Osaka Intex between the 7th and the 9th.

We will next be exhibiting at the Monozukuri Partner Forum taking place in Shinagawa from November 11th through the 12th.

From Wednesday through Friday of this week we will be manning a booth at the 18th Mechanical Components & Materials Technology Expo taking place at Intex Osaka. Please stop by our booth numbered 8-32 and show your face if you are in the area. We would be glad to answer any of your manufacturing questions or inquiries.

As is always the case when travelling to Osaka, we plan to go hungry and eats lots of delicious food!

During the [ Smart Energy Week 2015 ] taking place from February 25th through February 27th at Tokyo Big Sight we will be manning a booth amidst the Trial Production and Machining area. We will be displaying various products and our knowledge of die casting.

During the [ Smart Energy Week 2015 ] taking place from February 25th through February 27th at Tokyo Big Sight we will be manning a booth amidst the Trial Production and Machining area. We will be displaying various products and our knowledge of die casting.

Our booth is quite small but there will be two to three people ready to answer any questions so come and see us.

We will be at booth [ W9-3 ]

Happy New Year.

I would like to thank everyone for their continuing support.

With an obligation to meet the needs of our customers we have put significant effort into our manufacturing venue expansion and overseas related technology now supporting the technological development foundations at our head offices. With investments in 3 companies within Japan, and 4 more overseas (Thailand and Vietnam) amounting to 7 companies total, we have built a global establishment which takes into account risk management for disaster and global changes in dies, manufacturing, machining, and plating. This all I consider as a gift from the guidance of our customers and partners.

From here on, more than ever before I hope this all to serve as strength in answering the needs of all. We look forward to a year full of new die casting requests.

2012/4/1

Thai Akiba Co., Ltd. operations begin

On March 31, we held an opening ceremony and began operations at our manufacturing center in Thailand: Thai Akiba Co., Ltd., which was established in April 2011. In conjunction with the two sites in Vietnam, we are expanding our die cast design and global supply services our customer with complementary systems that span Japan, Thailand and Vietnam.

2010/6/29

We are currently accepting applications for die casting production engineers/technicians.

In order to increase die casting production technology in Japan, we are aggressively engaged in improving the manufacturing of equipment and die cast elemental technology. We are currently accepting applications for die casting technicians , or technicians/engineers skilled in equipment manufacturing technology, casting technology or metal machining technology. For all potential candidates, please contact the General Affairs Department directly or via email from the "Contact us" page.

2010/6/29

The Vietnam site operations for global supply began July 2010.

Our company completed planning for the manufacturing centers in Vietnam (Ho Chi Minh City and tỉnh Bình Dương) for die cast parts and die casting dies, and mass production operations began July 2010.

At present, our equipment manufacturing base includes four machines for aluminum die casting (500 ct: qty.1, 350 ct: qty. 1, 250ct: qty. 2 and 135 ct: qty.1) three zinc die casting machines (160 ht: qty.1, 60 ht: qty.1 and 20 ht: qty.1) and one die casting die manufacturing system. And, in order to continue to expand our manufacturing base to support the global supply needs of our customers, we are making arrangements to develop our equipment manufacturing line even further.

2007/11/20

We are global leaders in parts manufacturing using die casting and gravity casting on ALSiC-MMC (45% SiC content), which is lightweight and has high rigidity, high thermal conductivity and low thermal expansion.

Akiba Die Casting has begun a new business in ALSiC-MMC (aluminum silicon carbide metal matrix composite) die casting, large product casting and sheet forming.

ALSiC-MMC has been used as a raw material for more than twenty five years. Regardless of its excellent characteristics, it is generally only used in extremely specialized applications due to its high material costs and restricted machining usability.

We have been engaged in a joint research project with a materials manufacturer for 3 years, and we now lead the world in die casting with a high SiC content of 45%, that has been unattainable up until now.

As a material with a high SiC content, it has the following features:

(1) 2.4 times the coefficient of elasticity for high strength aluminum alloy (Young's modulus)

(2) Same level of high thermal conductivity as aluminum

(3) 2/3 lower thermal expansion coefficient than copper

(4) Abrasion resistance that exceeds cast iron (sliding abrasion)

(5) Same low density as aluminum alloy

Due to the excellent features of this material combined with our excellent die casting methods for mass production, we are developing trial manufacturing supplies for the market in applications for precision systems, structure materials and jigs (low thermal expansion, high rigidity and lightweight) such as robots and semiconductor fabrication systems, heatsinks that bond directly with ceramic substrates, abrasion resistant materials (high thermal conductivity, high rigidity and sliding abrasion resistance) for metal substrates (thermal deformation and stress control, high thermal conductivity), security parts (high strength and abrasion resistance), dampening parts (high attenuation) and brake rotors, etc.

We are currently receiving business inquiries from major electric appliance and automotive manufacturers that are global leaders.

(Sample picture)300 mm ■ Gravity casting sample (SiC 45% ALSiC) November 19, 2007: trial manufacturing

(Sample picture) 300 mm ■ Gravity casting sample (SiC 45% ALSiC) rib expansion

(Physical data PDF)ALSiC material features